February 23, 2017

Screen printing has long been a process that requires using hazardous chemicals that can harm the environment and cause health issues for its users.

As such, manufacturers have developed alternative products to lessen the impact of traditional ones. But how “green” are these alternatives and what impact do they have on shops using them?

For screen printers assessing their individual shops and how they can improve negative health, safety and environmental impacts, a good first step is to use the approach outlined in the sustainable business platform set forth by the Specialty Graphic Imaging Association (SGIA). It specifies three pieces to examine: people, practices and planning. To learn more, visit SGIA’s Sustainability Resource Center at sgia.org.

Rather than only examining the harmful chemicals in a specific product, you should consider the process as a whole, and how it affects the user and planet, if you want your business to be sustainable. After all, a business can be green, yet not meet sustainability criteria.

Inks are a prime example of this. Plastisol and water-based inks have different chemistries, but both can be used in a sustainable or green way. Because plastisol inks are petroleum-based, harsher, solvent-based chemicals are required to degrade them. Water-based ink commonly is viewed as greener because it can be cleaned using natural solvents and water.

But if water-based ink is dumped down a drain, it’s actually worse for the environment than plastisol because the pigments are finer and separate from the water in water-treatment plants. To be a sustainable company, you have to get a full life-cycle perspective on any product, from its ingredients to its use and disposal.

One way to make ink greener is to use a water-filtration system to capture as much of the harmful residue as possible. During this process, it is funneled to a holding tank or drum, which periodically is disposed of by a company that specializes in hazardous-waste removal.

“[Running water] through a water-filtration system not only makes the outgoing water safer, it also prevents anything from clogging up the drain,” says Brett Bowden, president, Printed Threads, Keller, Texas.

Bowden has a water-filtration system connected to his automatic screen-cleaning machine. It contains all the chemicals used and prevents them from being released into the air, and the filtration system removes the worst of the contaminants before they go down the drain.

Screen-Cleaning Chemicals

Using a process that prevents harmful chemicals from going down the drain is great for the environment, but not necessarily any safer for employees. Ensuring a process that protects employee health involves first using safer chemicals.

“Natural” screen-cleaning products have been around for many years, with new bio-product chemistry more recently joining soy- and citrus-based alternatives. Printers also should be aware that not all green chemistry is specifically marketed as such. This has been the case with many older manufacturers that have highly sustainable products. Therefore, it’s important to discuss with your manufacturer which of its products are more eco-conscious than others.

For those who really want to understand what makes a chemical greener, the United States Environmental Protection Agency has a list of criteria for green chemistry, which can be found at epa.gov.

Application Tips

In determining the sustainability of a process, consider how the chemical used therein is applied to the screen.

For example, anything in an aerosol can is not friendly to employees or the planet. Spraying a product from a pressurized can immediately disperses overspray into the air, where it can be inhaled or eventually land on a shop surface. The latter would create a film that could thicken over time if that surface isn’t regularly cleaned, becoming a collection spot for dust and lint.

Although an aerosol can is recyclable if completely empty, most screen printers simply toss it in the trash. And even if packaging is recyclable, not every shop’s local facilities can handle such waste.

A safer alternative is to use a comparable product that is dispensed as a liquid from a smaller container, such as a plunger can or a ketchup bottle.

“Instead of using screen opener that has to be sprayed on, we use a plunger can,” Bowden says. “You fill it with the chemical, and it has a plate on top. You place your cleaning rag on top of the plate and press down. It dispenses fluid onto the cloth while draining excess back down into the can. You can then use it to wipe down your screens.”

Closing the Loop

The more enclosed systems you can integrate into your shop, the more environmentally friendly it is. An example of a closed-loop system is an automatic screen-cleaning machine, which directly accepts cleaning chemicals. Dirty screens are loaded and the machine’s door is closed. No chemicals or fumes are emitted while the screens are washed.

Bowden has found this to be a viable solution for his shop with perks other than employee safety. “Screen cleaning has long been regarded as one of the most undesirable jobs in a screen-printing shop,” he says. “Having someone stand in a washout booth spraying chemicals for eight hours a day — even though they wear respirators and eye protection — is no fun.

“The beauty of having an automatic machine is everything is self contained,” he adds. “No chemicals get released into the air. Another plus is it cleans screens faster, so we get more done in less time. It used to take one person a full day to clean all of our screens. Now, they are done before lunchtime. That employee can now spend the second half of the day doing something else, so there [are] labor savings.”

Bowden only uses screen-cleaning chemicals with no volatile organic compounds (VOCs). “Not only are these chemicals safer for our employees to use, but because they don’t evaporate, they don’t have to be replaced as often,” he says. “We are able to use the same chemicals in our machine for three to four months at a time. We just top them off occasionally.”

Buying in Bulk

A shop can be even greener by buying products in larger quantities. Whether it be quarts, gallons or even a drum, larger quantities mean fewer containers left to be recycled or end up in a landfill. It’s easy to understand how much greener a 55-gallon drum is when you contrast it with disposing of 55 individual 1-gallon containers.

Many times, you can resell a drum or it can be used for another purpose, such as a trash can. Some printers use them as dirty-water or chemical-holding tanks. While buying a drum may be challenging for smaller shops on a budget, you get a better price for larger quantities, which may justify the expense.

There are many more ways to improve a shop in terms of safety and eco-friendliness. These are just a few ideas to help you get started. While being green sometimes is perceived as more expensive and less effective, that really is not true anymore. Research the new products and equipment available and experiment to see which solutions work for you.

Ryan Moor is the founder and CEO of Ryonet, a business he started in 2004 after printing shirts in his garage for his punk-rock band. Since that time, Ryonet has grown to 120 team members who have helped more than 100,000 screen-printing companies, from garage startups to award-winning ROQ automatic shops. For more information or to comment on this article, email Ryan at rmoor@ryonet.com or visit screenprinting.com.

March 20, 2024 | Production

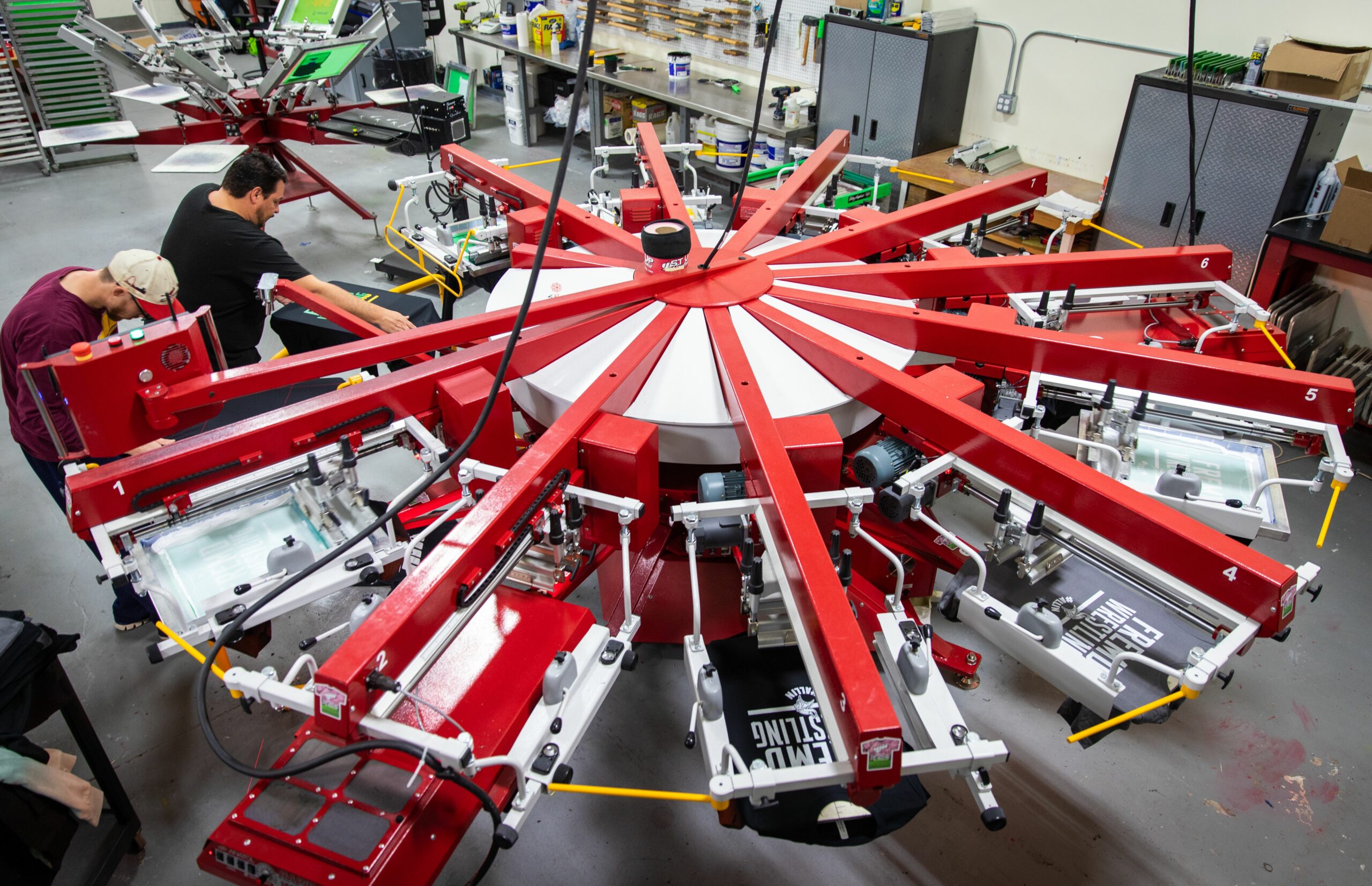

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY