February 12, 2016

Editor’s note: In the January issue of Impressions, Atkinson discussed the challenges with people and space that can lead to bottlenecks in workflow, and how to solve those issues.

In your screen-printing shop, if you’ve addressed issues dealing with time, workplace rules, staff and space, the good news is you’ve almost completed the path to smooth, efficient workflow.

But you’re not out of the woods yet. Peeling back the onion may reveal inadequately trained employees and — even worse — a lack of communication. Following are some ideas to address these areas in shops of various sizes.

Skills

One of the biggest challenges shops face today is the skills gap between veteran workers and newcomers. It’s been said that you are only as good as your worst employee, and there’s some truth to that.

What do you do to promote training, learning and developing your staff? Do you have a program? Does your shop just wait until there’s a problem and then throw someone into the fire to solve it? This industry is a mixture of art and science. We need craftsmanship to promote quality and creativity to set us apart from competitors. Learning the techniques and secrets of the trade helps achieve this.

What to do: Small Shops In some respects, smaller shops have an advantage because they can be more flexible. Learning a new technique is as simple as just doing it. Clean a screen and throw some discharge ink into it just to see what will happen. Many of the fantastic creative pieces seen in trade show awards programs are developed this way.

What to do: Medium Shops Create a training program, with the goal of having at least three people that know how to do every crucial task in the shop. This goes beyond just printing, as you need highly trained staff in all other departments too. One challenge for many medium shops is the person doing a job doesn’t want to train anyone or doesn’t want help. “Their way” works for them, so why change it? Usually, this person is worried that showing someone else how to do something makes him expendable. Demonstrate that having fully trained help can be beneficial in that there’s coverage in the event that there’s a work overload, or someone is sick or on vacation.

What to do: Large Shops Involve human resources in creating a robust training program. The idea is to have a cadre of staff trained in at least three departments. This not only creates coverage, but also opens up the opportunity for staff to discover that they are better at their new positions after training than they were in their old roles. It creates awareness for other departments and is a great motivator for employees. They see the company is actively involved in making them better employees, which makes them more valuable.

Communication

Make a quality effort to develop your company’s communication in all areas. Are you getting the right information from your client to create art correctly? Are you explaining the ordering and production process to them so they fully understand? How are you transferring the client’s intent for the order to everyone in the company that touches it?

Internally, examine how your group emails and talks to each other during the day. Are you giving the right information at the right time so the right decisions can be made and orders get processed more smoothly? That’s the sweet spot.

What to do: Small Shops When it’s only you, your communication is just directed to customers, vendors and the general public. Develop a marketing plan and some brand guidelines that communicate your shop’s awesomeness to the outside world. By having a core brand strategy, you can project professionalism beyond your shop size.

What do to: Medium Shops These shops usually include a few presses and two dozen people who all have to be informed on what to do. In this type of situation, it’s important to determine the best method of communicating so that it becomes standardized way. The faster someone understands what needs to be done, the quicker that task can be completed. The best way for this to happen is to include department-specific notes in your system for the order. These sometimes are printed on the work order or are loaded into the system and will pop up if a department member looks up a job. Either way, you are giving direction on what has to happen or recording a key bit of information that can be used to make a decision.

What to do: Large Shops When your shop becomes a certain size, it’s common for people to lose touch with others because they don’t have the same daily interaction that’s found in a smaller shop. The more shops grow, the more specialized the work becomes.

For communication, this can be limiting if you don’t add a dose of empathy to the mix. By this I mean that you have to be conscious of what might happen “downstream” from you. Did you just enter into your system 10 jobs that will use a dozen screens each? You might want to call the screen room and give them a heads up. Your staff can’t just leave things on a work order or shoot off an email and think everything is handled. Great teamwork involves championing the challenge, getting out of your chair or picking up the phone and discussing something with the affected department to ensure everyone is on the same page.

Marshall Atkinson is the COO of Visual Impressions Inc., and Ink to the People, Milwaukee. He also is a PromoKitchen chef. For more information or to comment on this article, email Marshall at matkinson4804@gmail.com.

March 20, 2024 | Production

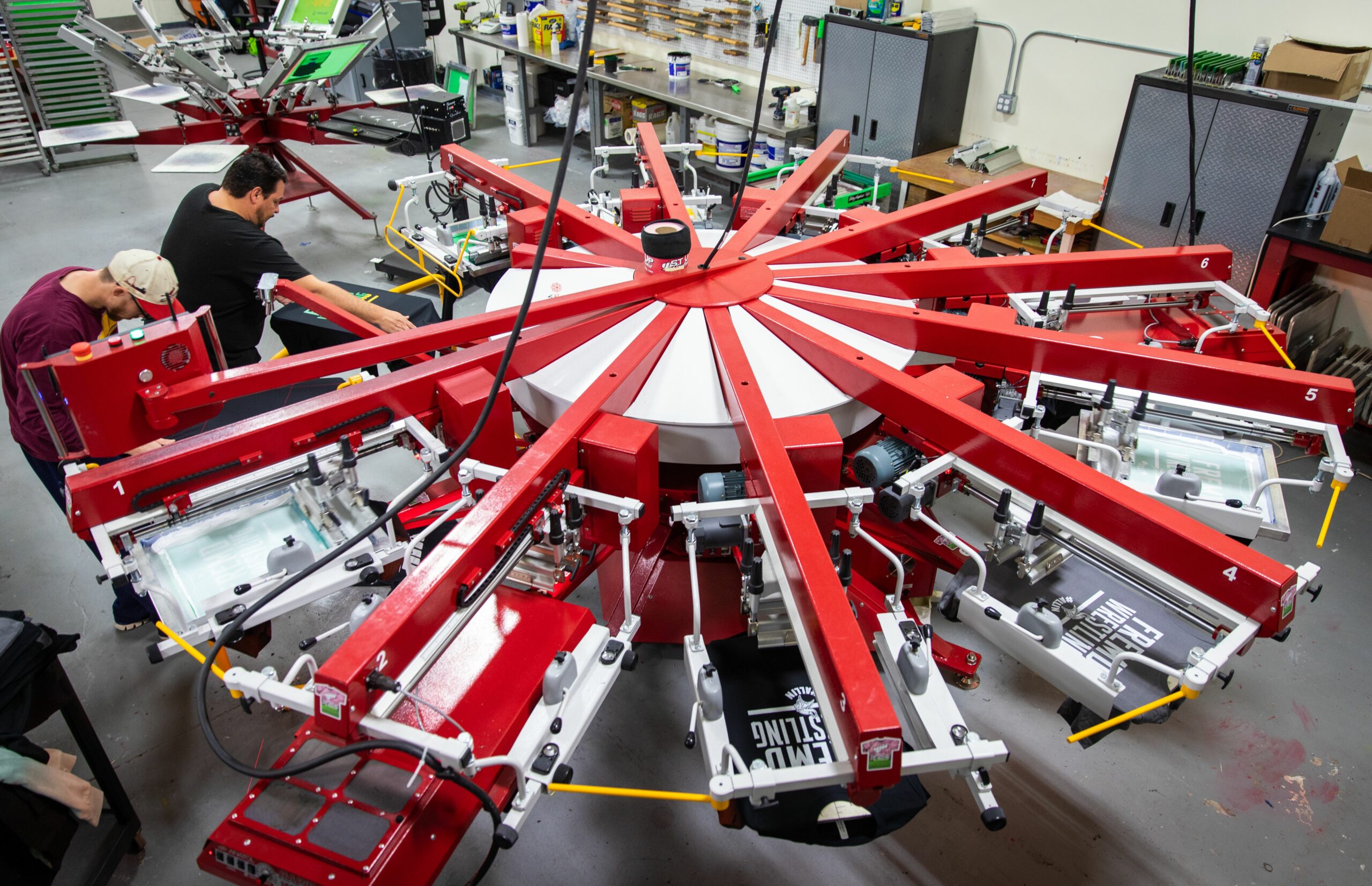

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY