September 5, 2014

In my last article (“Screen Exposure in a New Light, Part 1 of 2”), which appeared in the March 2014 issue of Impressions, I discussed newly emerging LED technology for exposing screens. It is available for conventional film screen exposure units and computer-to-screen (CTS) equipment. While more manufacturers are bound to jump on this bandwagon — and there is still information to come from beta testers and early adopters — there is no doubt that it offers distinct advantages over traditional offerings.

Here, I continue to discuss some of its primary advantages.

As mentioned in the preceding article, the biggest advantage of LED screen exposure equipment is its speed. Imagine exposing a screen in 20 seconds as opposed to 20 minutes.

In addition to decreased exposure time, another advantage of LEDs is reduced power consumption. LED banks use only a few watts of power versus the estimated 10,000 watts a current high-efficiency pinpoint metal-halide bulb might use. Because LEDs operate at such a low wattage, they also remain cooler. Thus, in addition to the lights costing less to operate, you can save money by not using cooling fans with larger exposure units or cranking up the air conditioner in the summer. Translation: Using less power means you’re paying less money.

Also, if you go from a unit that was pulling 10,000 watts to one that is pulling a few hundred, you may go from a 220 installation to a 110 installation. You can set up a more efficient facility layout and realize further savings by not needing special wiring when setting up a new shop or not having to call an electrician when reconfiguring your production area.

Another advantage being touted for LEDs is that they effectively will last forever. The reason is they have promised lifespans of 10,000 to 40,000-plus hours of “on” time. If your shop operates eight hours a day, five days a week, 12 months a year, that’s 2,100 hours each year. So if your LED unit is rated at 40,000 hours, you conceivably could operate for 20 years before having to replace it. Instead of spending up to $900 on a metal-halide bulb with a lifespan of, say, 1,000-2,000 hours, the LEDs offer a comparable upfront cost with the possibility of never needing to be replaced.

Since it is their tightly focused ultraviolet (UV) light range in combination with the correct emulsion that enables LEDs to yield such rapid exposures, can bulb aging cause spectrum shifts with LEDs, as it does with other light sources?

Over time, the specific inert gas and coatings inside a current incandescent or fluorescent exposure bulb combine with the aging of the electrical element to change the spectrum of the UV light that’s emitted. This typically adds to the amount of time required to fully expose the screen so it will wash out and print correctly. (I define this as “UV drift;” the tech guys will throw a fit over this description, but it works for me.)

For this reason, most current exposure units incorporate an integrator that measures UV output and adjusts exposure time to compensate for this UV drift. I personally have not seen integrators used with LEDs, and changes in UV output due to bulb aging may not be an issue.

As I understand it, heat is a primary factor in UV drift, and in theory, the lack of heat with LEDs may impact UV spectrum migration to the point where it is not an issue. No one has had a unit in place long enough to satisfy my curiosity, but it’s something worth exploring.

If we assume there will be UV drift, how does one compensate for it? With a single-point metal-halide light source, one bulb creates a cone of light that bathes the entire surface of the screen.

Detail is preserved because all of the light originates from just one point. With multipoint light sources, such as incandescent bulbs or fluorescent tubes, each bulb serves as a light source and emits a cone of light, each of which have zones of interaction.

One manufacturer describes its LEDs as being arranged in a specific pattern, or “interlaced,” at a specific distance from each other, at specific distances from the screen. This means interaction from the multiple light sources is eliminated, minimized or rendered a non-issue.

Although this could obviously make dealing with UV drift more complicated, I honestly do not see the potential for loss of detail as being great enough to impact most textile work.

Again, while the jury is still out due to the lack of market penetration at this point, I’ve observed that screen printed image quality using LED bulbs will not be a factor for the average T-shirt printer. There will be a few high-end printers who will contest that LED bulbs will not resolve a 2% dot. This will be of concern to a shop that prints decals or electronics, but unless you specialize in extreme fine-detail printing, you won’t have to worry about it.

IS LED FOR YOU?

So who could benefit from LED exposure technology? First of all, remember that a computer-to-screen (CTS) system is not required for LED use. There’s a lot of confusion about that in the marketplace. LEDs are being incorporated into exposure units in a variety of ways and at a range of price points.

They are offered as part of a CTS system, mounted to a traversing print head and in film-exposing units with a glass and vacuum draw-down. There are units designed specifically for LED technology, and some also have been adapted to incorporate LEDs.

They range in price from about $4,000-$70,000 or more when incorporated into high-volume CTS systems. For a couple of thousand dollars, you can even buy a kit to retrofit your fluorescent exposure unit with LEDs if it’s in good condition and you’re on a limited budget.

The next time I have to replace bulbs, I will choose this option. I already have a CTS system that images about 25 screens an hour, but I am very interested in no longer having to annually replace $400 bulbs.

Although high-volume shops with CTS systems will be among those really reaping the benefits of LED, any shop doing more than 30-40 screens a day should consider this technology.

If you are just getting into the business, I recommend that you consider purchasing an LED exposure system. It would be the wisest equipment investment from which you will get the greatest return. Do your homework, get and check referrals, track industry forums for comments, and look for YouTube videos to help you gather the information you need to make the best decision.

Greg Kitson is founder of Mind’s Eye Graphics, Decatur, Ind. For more information or to comment on this article, email Greg at greg@mindseyeg.com or visit mindseyeg.com. Hear Greg speak at the Imprinted Sportswear Shows (ISS). Discounts are available if you pre-register at issshows.com.

Changing With The Times

Some members of the decorated apparel industry are saying LED exposure technology is not all it is promised to be — and in its current state of development, they may be correct.

However, remember what probably happened at board of directors meetings at Kodak, Polaroid and other photo film suppliers during the 1990s. Some bright board member probably brought up the idea of digital photography for discussion and how it would be the wave of the future. The discussion then may have migrated to how it would change individual business models.

Another sage advisor probably stepped in to remind those in attendance that they were currently in the film business and had billions invested in its production, marketing and distribution.

In my opinion, what they missed was that they are really in the memory business and did not even realize it. The folks at Kodak had even copyrighted the term “Kodak Moment.”

We all know how this story turned out and how it affected photo equipment and supplies manufacturers. Keep this example in mind as you evaluate the future of LED exposure in the graphic arts world. Remember nobody needs another T-shirt; customers are buying memories that are conveyed via screen printed garments.

Suggested Reading

Like this article? Read these other screen printing articles at impressionsmag.com:

•

“Screen Exposure in a New Light, Part 1 of 2”

March 20, 2024 | Production

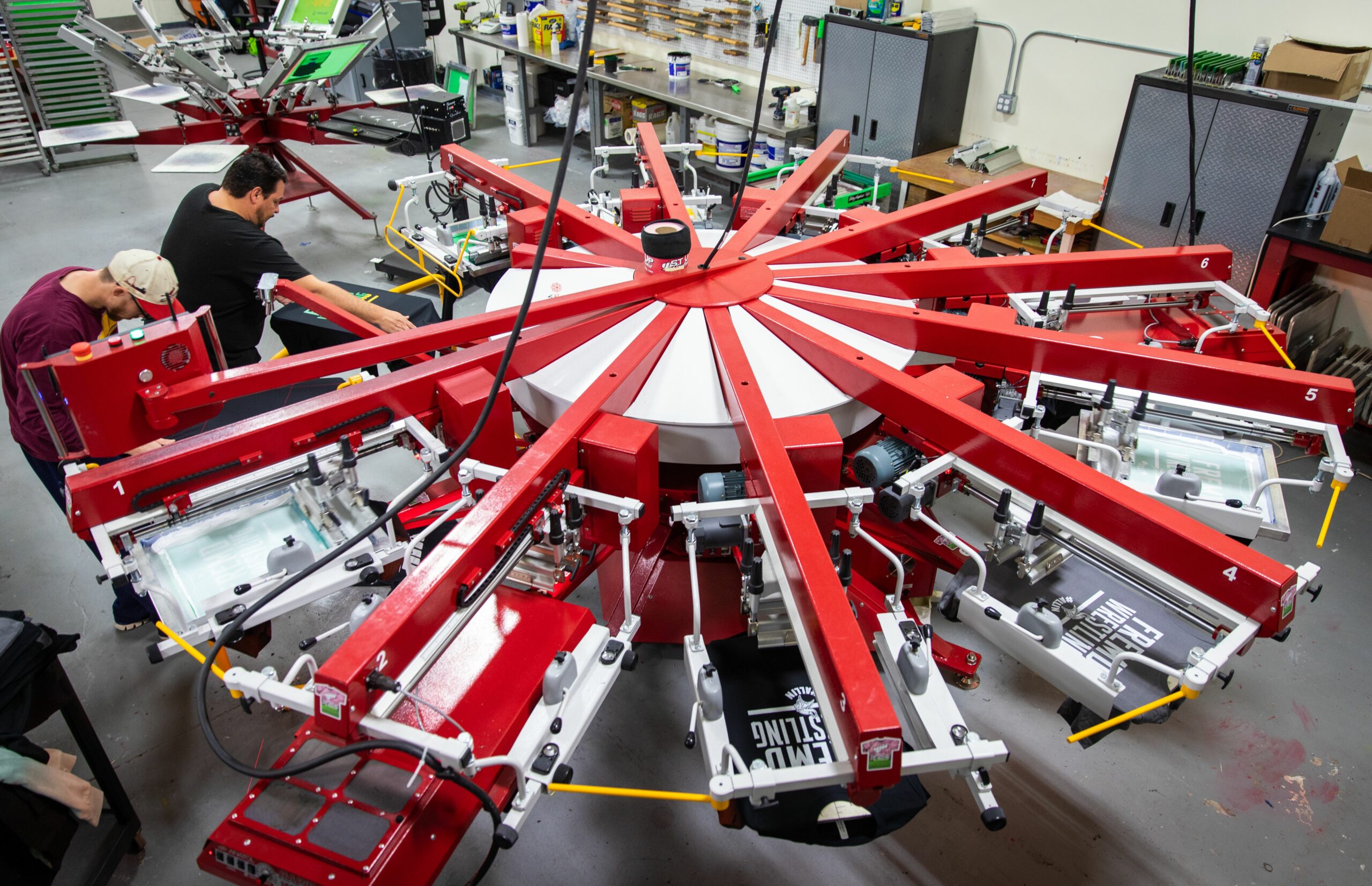

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY