August 12, 2013

As the cold season is coming, customers are stocking up on heavier garments like fleece. However, many printers shy away from printing on fleece because there are many variables that can make even a simple print difficult.

Fleece typically is made from a combination of polyester and other synthetic materials. It has a fuzzy side and a jersey knit on the other side.

Here are some tips on how to improve prints on fleece:

1. Since most fleece fabrics are made of polyester or a blend involving polyester, be sure to test the fabric for dye migration. Use ink that has good bleed-blocking properties, or one that is made for performance fabrics and can be cured at lower temperatures.

2. Due to the nature of fleece being double-sided, fabric movement during printing is a real concern. Stock up on pallet adhesive and be generous when applying it to the platen. Also, be sure to reapply the adhesive more often.

3. To combat dye migration, let the garments cool off after the curing process before stacking them. Many screen printers use a fan pointed at the cooling table. Just be sure not to point the fan toward the dryer, as the cooling air will change the temperature inside the dryer and may cause issues leading to under-curing.

4. Use a very tight mesh when printing, as this will help maximize the overall clarity of the image in the event that the fabric may move during the printing process.

5. Choose artwork that you can manipulate a little to make it easier to print. Rather than having registration requirements where different colors need to butt up exactly next to each other, create the artwork to overlap just a bit. That way, if the fabric moves a fraction during printing, the print will still come out crisp and without distortion.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

March 20, 2024 | Production

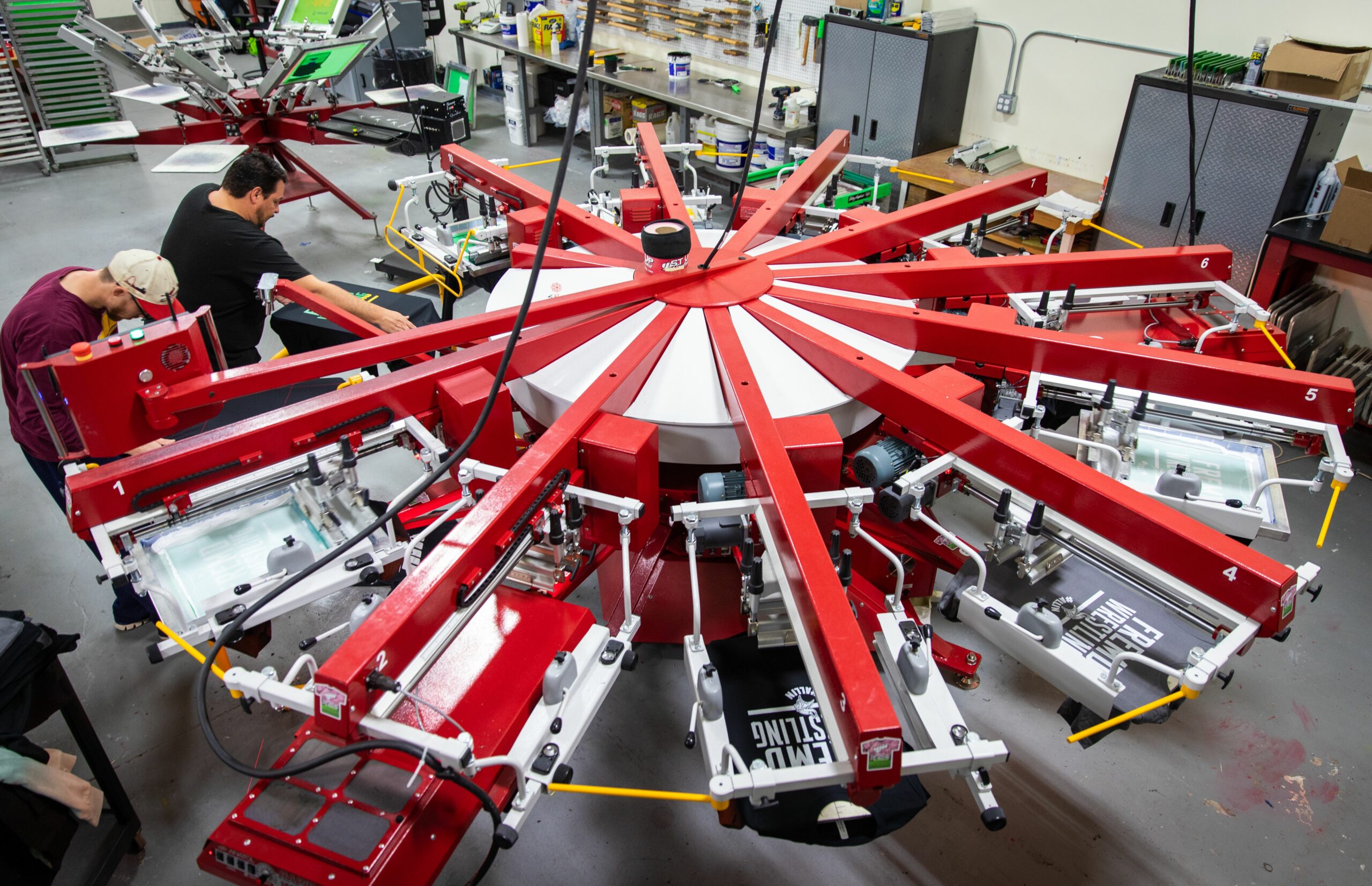

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY