January 11, 2017

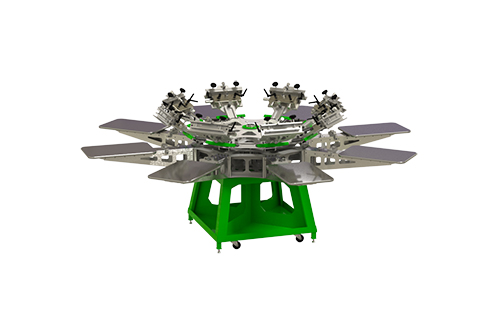

Ryonet Corp., Vancouver, Wash., offers a new generation of Riley Hopkins’ Riley500 manual presses featuring improvements and additions to enhance ease of use and durability in high-production settings.

The press’ CNC-constructed base now has a larger, 3-inch diameter post for more strength, and now includes a storage area. The print station assembly is lighter but still supports maximum press speeds. The Riley500 also is designed to work with the same ROQ lightweight, honeycomb aluminum platens that are used with ROQ automatic presses.

Registration also has been made faster and simplified for speedier setup with left and right anti-flip/anti-backlash ROQ xyz micro registration knobs. In addition, the presses now have a bearing style as opposed to a nylon bolt for easier locking into the registration gate. Ryonet’s unique two-point screen-locking system ensures continuous registration through long print runs and features a new grip clap surface, according to the company.

There also are hardened steel registration blocks for longevity; print heads now have a back center knob for tool-free off-contact adjustment and a front center knob for adjusting tilt. The presses also include right and left lever final tilt locks.

The Riley500 comes standard with heavy-duty back clamps or optional side clamps, and is available in four, six, eight and 10-color models. It also is ideal for large-format applications, according to the company. — J.L.

April 18, 2024 | Digital Decorating, Screen Printing

Stratasys Ltd. has launched what it describes as a new direct-to-garment (DTG) solution for its J850 TechStyle printer, the newest offering in the Stratasys 3DFashion direct-to-textile printing technology product line.

FULL STORY

April 17, 2024 | Industry, Screen Printing

The Women’s California Wave Wash Sunday Hoodie, offered by the Independent Trading Co., is the latest style in this collection, which also features crew necks, pullovers and full-zip styles.

FULL STORY

April 9, 2024 | Industry, Screen Printing

Per the research firm Future Market Insights (FMI) starting from a 2023 baseline of $3.4 billion, the custom T-shirt printing market in the United States is projected to reach $9.9 billion by 2033.

FULL STORY