August 6, 2018

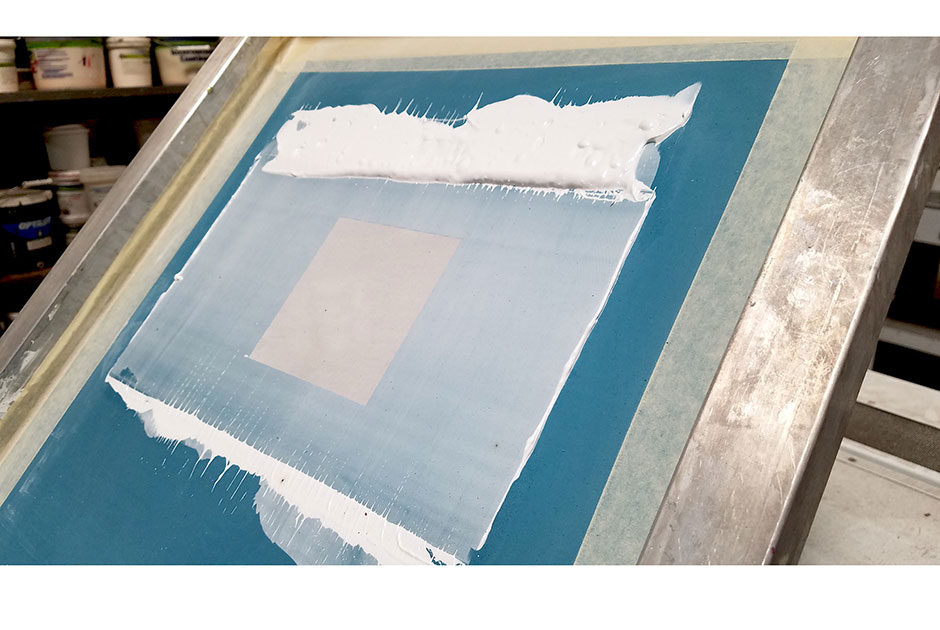

Confused about the different white inks on the market? Most printers understand the difference between a cotton white and a low-bleed white, but what about a mixing white vs. a highlight white?

Here’s a brief breakdown on which white to use for what:

- A Mixing White is going to be somewhat less opaque due to the fact that it is a mixing white and it is meant to be used in conjunction with other primary colors to make a Pantone formulation. It can be used by itself but will have limited opacity.

The other whites – Cotton, Low Bleed and Highlight whites generally have better opacity.

- A Cotton White is mainly used as a white underlay for dark garments, specifically cotton garments. It’s important to mention that cotton should be printed with a non-ghosting ink, which most inks meant for cotton are, because the fabric is prone to “ghosting” or bleaching when printed using some low-bleed inks or other inks that have bleaching properties.

- A Highlight White is generally printed on top of other white ink to give the white print a brighter, highlighted white. The ink may contain optical brighteners to make the white color pop.

- A Low-Bleed White is mainly used as a white underlay for dark 50/50 type garments. This type of ink has some dye bleed blocking properties, depending on the substrate.

- A Poly White is formulated for printing on 100% polyester garments and has a stronger dye bleed blocking property. Most poly whites also have additional elongation or stretch properties, so they can be used for printing on performance or athletic fabrics, including mesh shirts and bathing suits. Many poly inks now also cure at lower temperatures to help maximize its bleed blocking capabilities.

There are a couple other inks in this category that should be mentioned, although they are not “white,” they are used in conjunction with white inks to create an even stronger barrier to dye migration (bleeding) issues:

- Bleed Blocker Gray or Black are special inks (not regular gray or black inks) specifically formulated to block notoriously bleeding fabrics such as camouflage and popular wicking or performance fabrics. These inks typically contain a carbon compound that absorbs the dye and stops it from leaching into the white overprint.

These basic tips on white inks should help in determining which white ink to use for the particular job and substrate being used.

Mark Brouillard, International Coatings’ product manager, has considerable experience in formulating and manufacturing industrial compounds. For the past 16 years, his focus has been on the formulation and product development of textile screen printing inks. Brouillard coordinates the company’s product development efforts and deployments. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

April 12, 2023 | Sublimation

As you work toward becoming an experienced dye-sublimation apparel, general merch or customized promotional items decorator, you may come across one or more obstacles, like your transfers coming out blurry, dull or faded.

FULL STORY

June 1, 2022 | Sublimation

How many times have you wished that you could sublimate a product that wasn’t polymer-based or polymer-coated.

FULL STORY

October 8, 2021 | Sublimation

I think the philosophy of lagniappe should be taught at every school and practiced by every business. A French word meaning “unexpected extra gift,” lagniappe often is used in Louisiana. In fact, sublimation decoration is a fantastic example of this.

FULL STORY