August 10, 2016

Sublimation production systems typically fall into one of two categories: narrow (desktop) or wide-format. The traditional dividing point between these two formats is 42 inches of printing width. Generally, anything greater than that width is considered wide-format sublimation; anything less is considered desktop format.

In addition, wide-format printers use paper rolls, while most desktop printers use single sheets of paper. Thus, wide-format systems can produce much larger images than those generated by desktop units.

However, there are some quality printers in the 24- to 41-inch range that — while not considered wide-format — offer all the benefits of the larger systems in a smaller package with a lower investment. With this “crossover” class of printers, there are more options than ever for shops looking to move into wider-format printing.

Most sublimators start by using desktop equipment rather than larger systems simply because the investment is quite low. With printer prices starting at about $600, the desktop format is quite affordable, especially if you already have a heat press. Even if you need to buy one, a quality, decent-sized unit starts at about $1,500. Typical products that can be sublimated with desktop systems include cell phone covers, apparel, awards, plaques, promotional products, signage, photo panels, drinkware, etc.

Desktop printers are characterized by their maximum media size. The small units can print on paper up to 8.5″ x 14″, while larger ones can handle up to 13″ x 19″ paper. However, these printers do not print to the edge of the paper, so maximum image size always is slightly less than maximum media size. Though many popular sublimated items can be produced using these systems, wide-format systems open the doors to a significant range of larger products or large-scale production of smaller products.

Printing Large Products

Wide-format and desktop sublimation involve the same chemistry. Sublimation dye is applied to sublimation transfer paper, which is then applied to a polymer-coated or polyester substrate in a heat press. The combination of time, temperature and pressure causes the sublimation dye to turn into a gas, which combines with the polymers at the molecular level. The paper is discarded and a permanent image is left behind.

With a wide-format operation, the first and most obvious advantage is image size. That means either finished products with large images or bulk goods with continuous graphics.

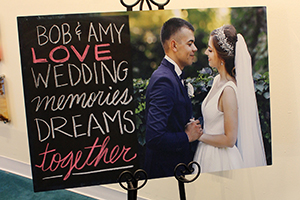

In terms of large, finished products, signage is one of the top uses for wide-format sublimation. Full-color graphics, text and photos can be combined to create stunning visual messages for businesses, events, public areas, etc. Coated metal is a popular substrate for signage and is available in a wide range of precut sizes. In addition, coated metal panels can be custom cut in a variety of sizes, as needed. Tabletops, typically manufactured for use in coffee shops and small-scale eateries, are another unique substrate available for signage.

Beyond signage, wide-format sublimation can be found on architectural panels that are integrated into the design of a building. In other cases, it can be used to reproduce fine art or professional photography for wall-mounted panels.

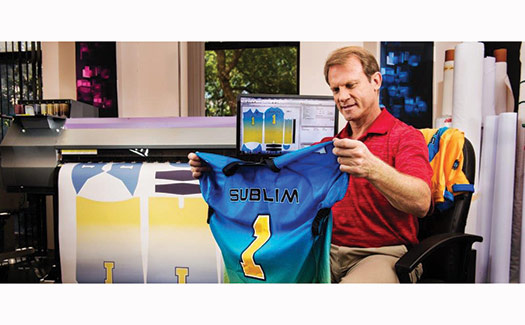

Also, wide-format sublimation also is popular with finished garments, with the most common application being allover sublimation. When applied to apparel, this process provides a huge revenue opportunity, as it creates unique products with a higher perceived value. However, the production costs are quite low.

Also, fabric color is never a concern because you simply start with a white garment and then recolor it via the

application of the image. This means virtually any shirt color can be created and successfully printed. Essentially, you are printing white without white ink. And since sublimation will not crack, peel or fade when laundered, it will outlast

the garment.

The garment must be made of polyester fabric, but with the huge popularity of poly-performance garments, there are plenty of apparel options available

for sublimation.

Other large-area finished products include, flags, banners, towels, quilts,

blankets, etc.

Bulk Production

A different direction for wide-format sublimation is the production of bulk goods, most of which involve fabric, but not finished goods. These products usually are delivered to cut-and-sew operations, which turn them into fabric-based products. In the case of specialty operations, the printed material is converted into a finished product on site. Examples include apparel, upholstery, tapestries, trade show backdrops, overhead exhibition signs, pull-up banners and table covers.

Traditional sublimation on finished products requires a flat press, which must be larger than the largest printed image. With bulk fabric goods, a calendar press typically is used. It consists of a series of heated rollers through which the paper and fabric pass. This provides the necessary time, temperature and pressure on a continuous-feed basis. Considering that paper rolls can be hundreds of yards long, a lot of fabric can be printed in a single production run.

In addition to large individual pieces and bulk-goods production, wide-format printing also is commonly used to produce large volumes of smaller, individual substrates.

For example, if you had a 44-inch-wide printer and needed to produce an order for 100 6″ x 6″ sign panels, you could use the copy-and-paste function of your graphics software to maximize printing so that each run produced multiple images — six images across by 17 rows long. This is too long for most heat presses, so some cutting would be necessary.

However, you could mate up sections of the transfer — within reason — with blank substrates in order to take advantage of a wide-format heat press’s large area. It also should be noted that roll-feed printers measuring 24 inches or greater have paper-cutting functions.

Inks & Cost

Wide-format printers usually are eight-color systems, whereas desktop units

typically are four-color systems using CMYK inks. With the former, the additional base colors increase the overall color range that can be produced and enhance the imaging in certain applications such as Pro-Photo, where accurate facial skin tones are crucial. Specialty inks that are developed specifically for this application can deliver top-quality photo images in a high-definition format.

Other unique sublimation products include fluorescent spot-color and UV-resistant inks. It should be noted that sublimation is not truly UV-resistant, but new developments have yielded inks with more UV stability.

Moving up to wide-format printing requires a larger investment. Available in a range of sizes and options, the prices for wide-format printers typically start at about $6,000 and increase sharply. There also is the heat press aspect, as you will need a unit that corresponds in size to your printing capabilities. This easily means shelling out another $10,000 or more.

On the surface, wide-format sublimation can look appealing, but you must be sure it’s the ideal solution for your needs. From a production standpoint, how often are you doing large-volume runs? Does it really justify the cost, or should you contract it out? If your jobs are more about customization and personalization, wide-format sublimation rarely makes sense. In fact, you actually can get more effective output in many situations with a smaller printer if you tweak your production process by adding a larger heat press. It’s important to note that wide-format printers are not necessarily faster than small-format units — and may even be slower.

Your production needs should dictate the system that best fits your business model. The idea of being able to print any color T-shirt using wide-format technology is cool, but if you’re not doing high-volume production on a daily basis, you probably should contract those jobs out.

If you decide to go down the wide-

format sublimation road, remember that larger printers come in a variety of printing widths, so there are plenty of options to consider. A good rule of thumb is to purchase the smallest printer that can produce the largest image needed. This will ensure you are seeing the best return on investment for your equipment choice, while also gaining all the benefits of wide-format sublimation.

Award-winning author and speaker Jimmy Lamb has more than 20 years of apparel decoration experience. He currently is manager of communications for Sawgrass Technologies. For more information or to comment on this article, email Jimmy at jlamb@sawgrassink.com.

April 12, 2023 | Sublimation

As you work toward becoming an experienced dye-sublimation apparel, general merch or customized promotional items decorator, you may come across one or more obstacles, like your transfers coming out blurry, dull or faded.

FULL STORY

June 1, 2022 | Sublimation

How many times have you wished that you could sublimate a product that wasn’t polymer-based or polymer-coated.

FULL STORY

October 8, 2021 | Sublimation

I think the philosophy of lagniappe should be taught at every school and practiced by every business. A French word meaning “unexpected extra gift,” lagniappe often is used in Louisiana. In fact, sublimation decoration is a fantastic example of this.

FULL STORY